Beyond Eradication: The IPMS Roadmap to Audit-Ready Warehouse Pest Control

For a warehouse operator in Singapore, a pest sighting is not a small problem—it is a compliance failure waiting to happen. Whether you manage dry goods, pharmaceuticals, or general logistics, your profitability and reputation are staked on maintaining a pest-free environment that adheres to strict international standards like AIB International and HACCP.

If your current pest control plan still relies on a technician showing up for a routine spray, you are falling behind. That approach is reactive, non-compliant, and ultimately ineffective.

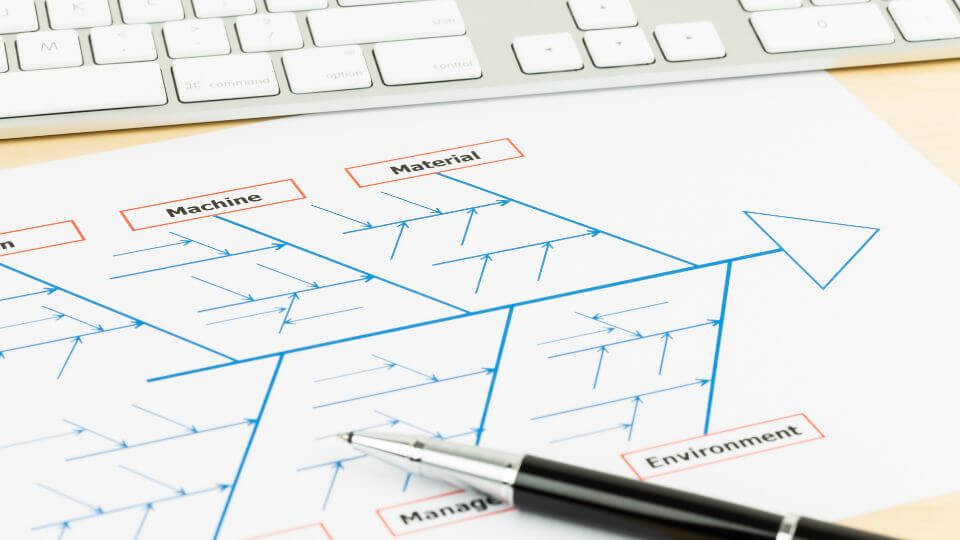

The modern, professional solution is a properly implemented Integrated Pest Management System (IPMS). This is not just a service; it is a scientific, data-driven security protocol designed for sustainable, long-term risk mitigation.

The A-Flick Distinction: Scientific and Sustainable

What truly separates an A-Flick IPMS from traditional pest control is our focus on Root Cause Analysis (RCA). Our objective is not merely to eliminate the pests we see today, but to identify and correct the structural or procedural failure that allowed the infestation in the first place. This sustainable approach ensures the problem does not recur, delivering permanent facility security and maximizing your investment.

The A-Flick 3-Layer Defense Strategy: Rodent Control

Rodents—Rats and Mice—are arguably the most destructive and compliance-threatening pests in any commercial setting. Our defense system is engineered for maximum security and minimal risk, meeting stringent food safety guidelines like AIB and YUM! standards.

| Defense Line | Location | Purpose | Materials |

|---|---|---|---|

| 1st Line: Exterior Perimeter | Outside the building, surrounding the perimeter. | Interception and population control before entry. | Tamper-resistant, anchored Bait Stations with approved rodenticide blocks. |

| 2nd Line: Internal Perimeter | Along interior walls, dock doors, and high-risk zones. | Early detection of invading pests and secure capture. | Glue Boards or other secure trapping devices only, prioritizing product safety. No bait is used internally. |

| 3rd Line: Sensitive Areas | Inside processing areas or direct storage zones. | Zero-tolerance, non-chemical capture and monitoring. | Glue Boards or other secure trapping devices only, prioritizing product safety. No bait is used internally. |

All internal stations are strictly traps (no bait) to eliminate the risk of chemical contamination or off-target poisoning within the facility, a non-negotiable requirement for HACCP programs.

Targeted Monitoring: Pinpointing the Threat

We replace guesswork with hard data across all major pest categories:

General Crawling Pests (Ants and Cockroaches)

The presence of Ants and Cockroaches signals a lapse in sanitation or exclusion. We strategically place non-toxic monitoring devices in high-risk areas like pantries, staff toilets, and dark machinery spaces. Catch rates are logged, providing data on the type and volume of pest pressure, allowing us to pinpoint harborages for targeted (and minimal) intervention.

Flying Insect Control

- Method: We install UV Light Traps (Insect Light Traps or ILTs) in non-food preparation areas and entry zones.

- The Data: Trap counts are regularly analyzed to identify pest spikes, helping us to pinpoint the source of entry (e.g., a cracked door seal, an unmanaged dumpster) rather than just treating the symptom.

Stored Product Pest (SPP) Control

- Method: Pheromone Traps are deployed in storage racks and high-risk commodity areas.

- The Data: Monitoring catch rates provides the earliest possible warning of an infestation. This allows for a swift, localized intervention—often before the contamination spreads.

Stored Product Pests require specialized knowledge. To understand how prevention, exclusion, and control of pests like Cigarette Beetles and Flour Beetles are done using the A-Flick’s way, check out this post.

From Threshold to Solution: Root Cause Analysis

When monitoring indicates a breach of the agreed-upon Action Threshold, we enact the most important step: Root Cause Analysis (RCA).

- The RCA Process: We systematically investigate the environmental and procedural failures that led to the breach. We use techniques like the “5 Whys” to dig past the symptoms.

- Exclusion & Repair Advice: As part of this service, A-Flick identifies and advises customers for repairs and exclusion (e.g., sealing gaps, installing screens) to permanently block future pest access. This structural defense is the most sustainable form of pest control.

This rigorous, documented process is what satisfies global quality audits and gives you true peace of mind.

Secure Your Compliance, Secure Your Audit

An IPMS is an investment in your warehouse’s reputation, compliance, and operational efficiency. It transitions you from the unpredictable costs of crisis management to the predictable, documented security of a preventative system.

A-Flick provides the technical expertise and the paper trail necessary to stand up to any regulatory body or quality auditor.

Stop risking your product and your reputation on outdated methods. Let A-Flick build you an IPMS that works as hard as your business does.

Contact A-Flick today for a professional consultation and IPMS compliance assessment for your Singapore warehouse.